the best band saw factory In China

Automatic band saw Machine

With over 40 years of band saw machine manufacture experience, LUBAN is honored to carry the TUV logo due to its adherence to TUV’s strict standards and regulations. We have been approved for 6 TUV certifications in a 20-year span.

Your Trustful Automatic band saws Supplier

LUBAN is one of band saw machine manufacturers in China since 1982. As a leading & professional China-band saw machine factory with over 20 years TUV certification, our company manufacturing automatic band saws and cnc band saws design, such horizontal band saws, metal band saws, heavy duty band saws, large band saws, miter band saws, double column band saws, and steel band saws. Contact us today to request a free quote or more information.

Want your own band saw? Look no further! LUBAN is your one-stop-shop for everything band saw machine. We are a bandsaw-based company that takes pride in our superior cu.stomer service, sending you the best bandsaw products to your workshop. Click the button below to find what you’re looking for.

REQUEST A QUOTE FOR MORE DETAILS

Automatic Band Saw: What It Is and What It Is Used for

An automatic band saw is a fully automatic metal band saw machine, which is suitable for batch cutting and factories pursuing automated cutting.

One operator can operate 4-6 sets automatic band saws at the same time, greatly liberating manpower.

Suitable for fully automatic cutting of various metal materials.

Why Choose an Automatic Band Saw?

An Expert's Advice

Investing in the right automatic band saw machine is pivotal.

It can transform your production by reducing costs, improving efficiency, increasing profits, and speeding up deliveries. However, to reap these rewards, you must select a machine that aligns perfectly with your requirements and upholds unwavering quality. This is the starting point.

Efficiency

When it comes to high-volume cutting, the automatic band saw stands out for its efficiency. This type of band saw minimizes waste with its precision cutting, offering a cost-effective solution for your fabrication needs. Its capability to handle large stock and maintain a uniform cutting performance is pivotal in industrial settings.

Precision

The design of automatic band saw allows for precise control over the cutting process, which is critical when exact measurements are a must. Ensuring that each cut is as accurate as the first, making it indispensable for machine tool traders who demand perfection.

Durability

Durability is a cornerstone of band saw machine’s construction. Built to withstand rigorous use, the components of these machines resist wear and tear, translating to fewer breakdowns and maintenance interruptions. This means a reliable tool that upholds continuous operation with less downtime.

Safety

With operator safety in mind, band saw machine incorporate various features to protect users. These include automatic shut-offs and blade guards, which not only ensure the well-being of the operator but also contribute to the smooth functioning of the production line. This commitment to safety is crucial for machinery traders who prioritize worker protection.

Cost

The cost-effectiveness of employing a band saw machine in your operations is undeniable. Its energy-efficient design reduces operating costs, while the machine’s multi-functionality means it can replace several other machines. For machinery traders, this equates to a smart, long-term investment that can significantly enhance your customers’ operational profitability.

Factors To Consider When Purchasing an Automatic Band Saw

Purpose

What is a band saw machine used for? Is it to increase production or improve cutting accuracy? Is it used for material cutting?

Type

The type of band saw machine affects the cutting results, and you need to choose the right one based on the characteristics of the material. Additionally, the wrong type of band saw may result in an inability to cut properly.

Some types of band saw machines are suitable for cutting bars, profiles, pipes, and H-beams. Some types are suitable for cutting sheet metal. Understanding the type and how it works with metallic materials is an important consideration.

Structure

Different band saw machines sructures indicate different rigidities. It is also a reflection of the technical capabilities of the band saw manufacturer. From the original intention of R&D and design to the user’s use effect, it basically determines everything.

Drive

If you require throughput, drive is a factor worth considering. Heavy materials require a large band saw machine, while light materials are suitable for small to medium-sized band saw machines. Of course, you also need to select the specifications of the band saw according to the cutting size of the material.

Material

The material of the band saw machine is important because it ensures the band saw’s stability and long-term operation. Choosing inferior materials means a shortened lifespan for your band saw.

Performance

If you’re looking for performance, the component configuration of your band saw is quite important. For example, core configurations such as electrical, PLC system, hydraulic system, motor, reducer, etc., their origin, brand, specifications and coordination greatly affect the cutting efficiency of materials.

In addition, these core configurations are the main source of the quality performance of the band saw machine.

Feeding

According to different band saw machine specifications, different feeding racks need to be selected. You can decide whether to use manual or electric based on the material. If it is made of light material, you can choose from both; if it is made of heavy material, it is recommended that you choose the electric one. Its use in conjunction with a band saw will allow you to better reduce labor intensity and make it easier and more convenient.

Industry Standard

Band saw machines follow certain standards. With this in mind, there are standards for band saw materials. There are standards for the production of band saws. It is important that band saws comply with the strict regulations imposed by international agencies. This ensures safe use and fulfillment of cutting requirements for band saw users.

Band saw supplier

When considering purchasing a band saw machine, the band saw supplier is the point of contact. The band saw supplier should provide the customer with the appropriate band saw manufacturer.

The former is responsible for informing customers of industry standards and other considerations. He should be able to provide the right product at the right price. He should also understand the customer’s needs and the right type of band saw for a specific industrial application.

How Does the Configuration Of an Automatic Band Saw Affect You?

Electrical

Every band saw machine’s prowess begins with its electrical system. Utilizing advanced circuitry ensures reliability in your operations, streamlining your workflow with precision.

Control

The integration of top-tier Programmable Logic Controllers in band saw machines promises adaptability and efficiency, optimizing your metal cutting process for various materials.

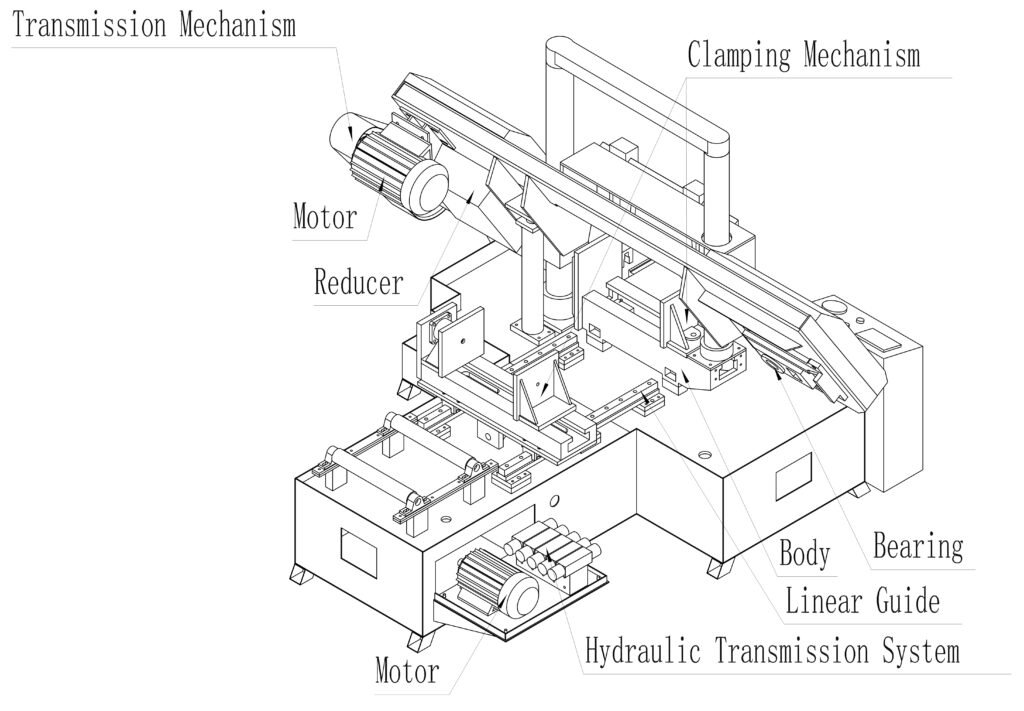

Bearing

High-caliber bearings are pivotal in band saw machines, ensuring smooth operations and longevity, which translates into a steadfast performance in even the most demanding tasks.

Motor

The heart of a band saw machine, its motor, commands power and control, driving cutting-edge performance that metalworking professionals can rely upon day in, day out.

Linear Guide

Precision in metal cutting is non-negotiable. band saw machines equipped with superior linear guides deliver accuracy, enhancing the quality of every cut.

Reducer

A robust reducer in a band saw machine ensures consistent torque management, which is crucial for maintaining cutting efficiency and precision under various loads.

Hydraulic System

The hydraulic system in band saw machines lays the foundation for controlled and stable operations, supporting a seamless cutting experience across diverse material types.

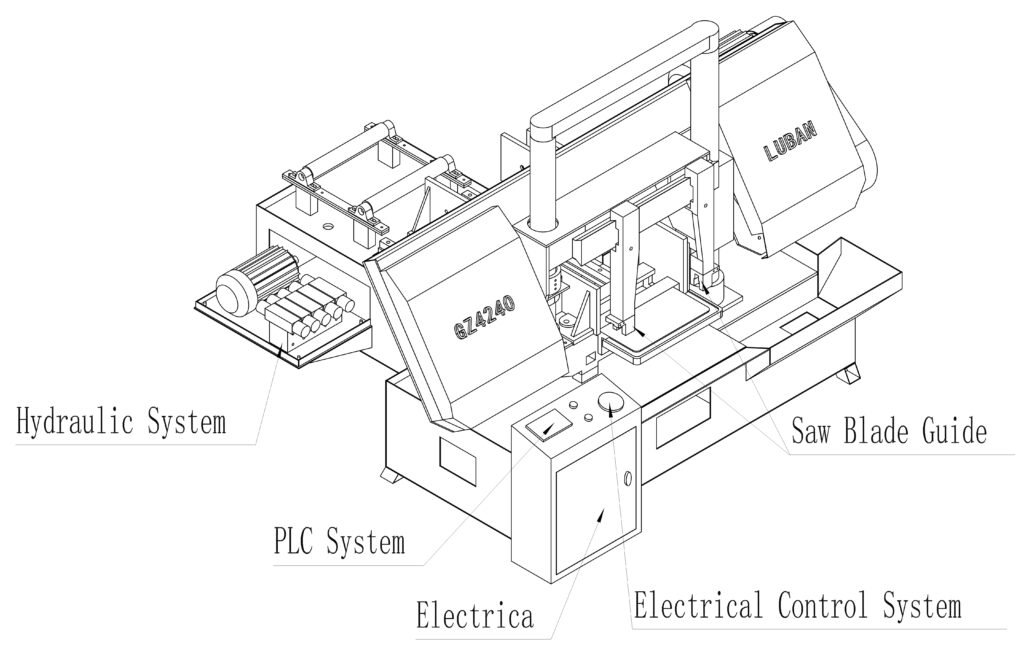

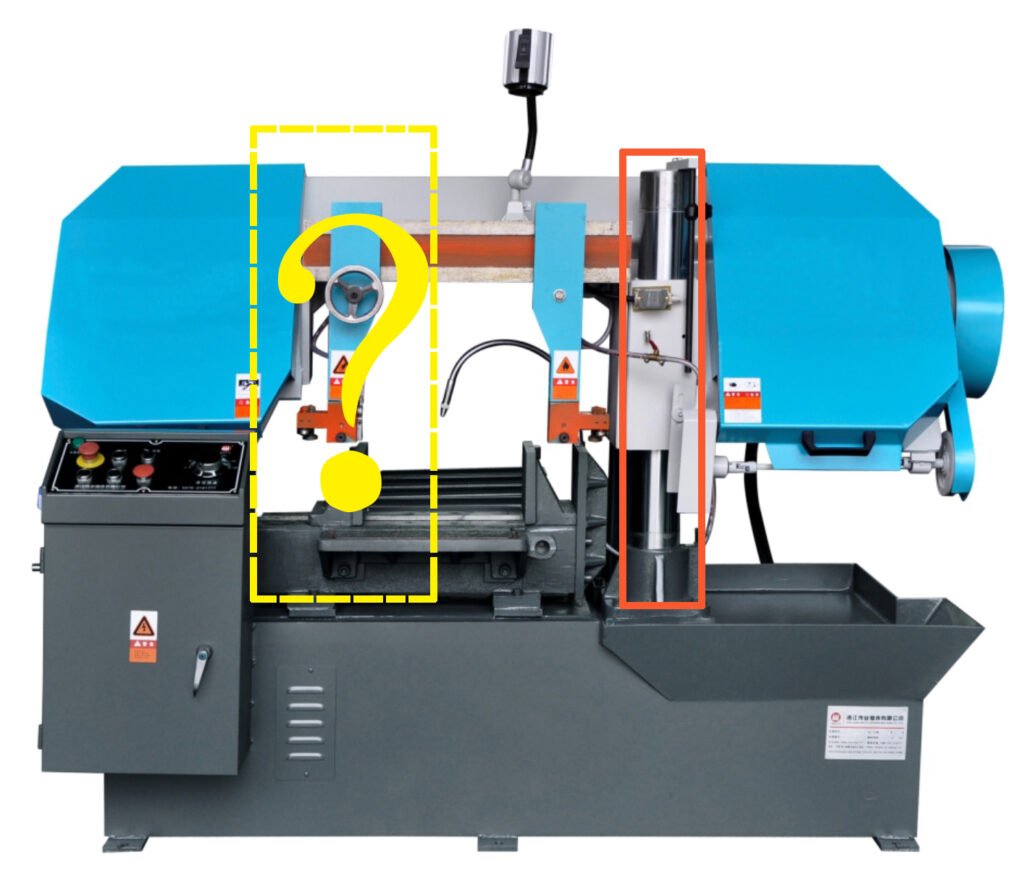

Automatic band saw design

LUBAN automatic band saw is made of high-quality materials and complies with industry standards and specifications.

It has a sophisticated PLC operating system and a highly stable and rigid double column structure, making it extremely reliable and easy to maintain.

- Band saw components: saw beam, column, bed, bottom box, PLC system, hydraulic system, transmission system, and feeding system.

- Band saw running: after entering the cutting data and clicking "Start", the band saw will run automatically.

- Band saw specifications: 280*280 - 2200*2200mm.

- Band saw features: automatic measurement, automatic feeding, automatic cutting, automatic standby after completion.

Automatic Band Saw: Component Configuration

LUBAN uses world-class power components to enhance the performance of automatic band saws.

- Electrical: Schneider, France

- Bearing: NSK, Japan

- PLC: Siemens, Germany

- Motor: Siemens, Germany

- Linear guide: Yinlei, Taiwan

- Reducer: Boxin, China

- Hydraulic system: LUBAN, China

Automatic Band Saw: Optional Configuration

Frequency conversion

The knob adjusts the speed of the band saw blade, and the speed range is 0-80m/min.

Automatic Band Saw: Optional Configuration

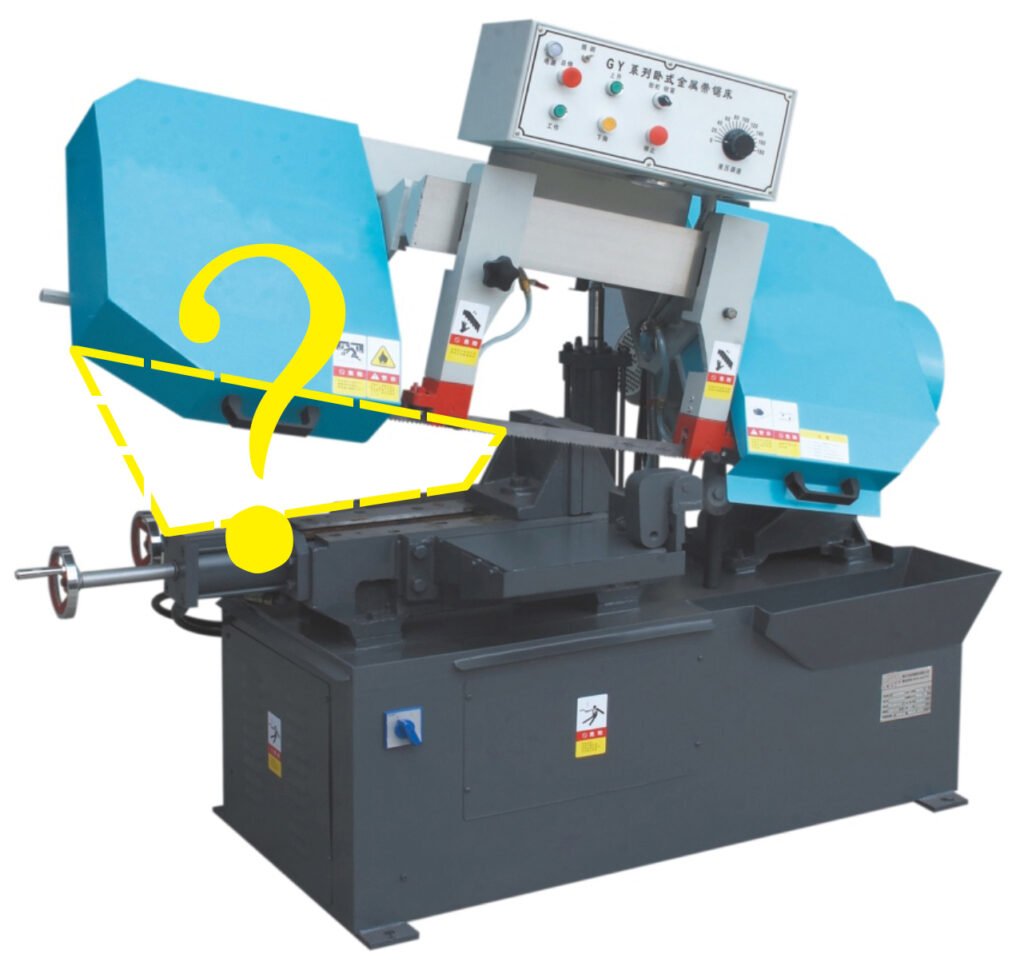

Single-Column Automatic Band Saw

Its may be a budget-friendly pick, but with challenging materials, it can wobble, affecting cut accuracy. If your projects involve heavy or thick metals, this could mean more waste and redoing work, hitting your efficiency hard.

Scissor-Type Automatic Band Saw

It offer simplicity, yet the single pivot design struggles with consistency over time. This leads to more blade wear and potential inaccuracies, a costly downside when precision is your top priority.

Double Column Automatic Band Saw

It is the champions of consistency. With double columns for support, they bring you the stability needed for exact cuts, even on the most formidable metals. This means less waste, less blade changeover, and more confidence in every cut.

Automatic Band Saw: Types By Craftsmanship Design

90 Degrees Automatic Band Saw

A 90-degree cut is a common process for metal band saws, also known as a 0-degree cut or a right-angle cut. It is generally used to cut long materials into various short materials.

45 Degrees Mitering Automatic Band Saw

Before diagonal welding of metal materials such as profiles, 45 Degrees cutting is usually performed with Mitering cutting metal band saw. The cutting surface must be kept at a precise angle, clean and flat before it can be used in the butt welding process.

What to Look for in a band saw machine Supplier / Manufacturer

Industrial certifications

A good band saw machine supplier or manufacturer should have industrial certifications. This shows that the products available are of top quality because these have passed rigid regulations. The industrial certifications imply that the work area has been checked and assessed according to the requirements of the governing body.

Variety of band saw machines

A good band saw machine supplier has a wide array of band saw machine and band saw components. The manufacturer should have clear and reachable timelines expectations. Furthermore, with a large inventory, the manufacturer assures the customer that the component needed is readily available.

After-sales service

A band saw machine need repairs. A great band saw machine supplier should give after-sales services.

Commitment to safety

Safety is an issue in process industries. Because of that, regulations become more strict and change every now and then. A good supplier of band saw machine should be able to adhere to these changes.

Request A Free Quote

We'd Like To Work With You

Send us a message if you have any questions or request a quote.

Our experts will give you a reply within 24 hours and help you select the right band saw machine you want.

- +86 182 6527 8599

- +86 182 6527 8599

- luban@lubancncmachine.com