How to cut reasonably to reduce the cost of metal band saw?

Heat and vibration are the worst enemies of metal band saw machining. Both phenomena are easy to define, but analyzing why heat and vibration occur is more challenging. Proper analysis and adjustments through observation are very important to optimize the performance of the band saw. When the band saw is in working order, cuts will be smoother, straighter, and faster, resulting in lower cost per cut.

The Correct Choice of Metal Band Saw Blades

Properly selecting the right metal band saw blade for your specific application is crucial. First, the cutting scenario should be analyzed. The type and status of the band saw, the processing performance of the material, the specification and size of the material, and whether the material is clamped for single-piece sawing or multi-bundle sawing determine which metal band saw blade should be used. These factors also determine the band saw line speed and feed speed settings. Some users choose metal band saw blades blindly based on price. In fact, metal band saw blades have very different performance due to the stability of their manufacturing processes and the different R&D levels of each manufacturer. Therefore, they must choose metal band saw blade brands rationally.

After determining these key factors, the correct tooth pitch (TPI) must also be selected. The rule of thumb for optimal sawing performance is to saw with at least three teeth on the workpiece and no more than 24 teeth. Having 6 to 12 teeth participating in sawing on the surface of the workpiece has been proven to be the most effective tooth pitch (the author will choose 12 teeth in most domestic sawing scenarios). For difficult-to-cut materials, the tooth pitch should be smaller. It is recommended to choose 24 teeth.

Belt speed and feed speed settings for metal band saws

After selecting and correctly installing the metal band saw blade, set the belt speed and feed speed. Belt speed refers to the running speed of the metal band saw on the surface of the processed material. A faster belt speed will have a larger shearing angle. Belt speed will be limited by the processing properties of the material and the heat generated during sawing. Using too high a belt speed on hard metal will generate too much heat, causing rapid wear of the tooth tips and shortening the life of the band saw. Material properties are the overall determining factor in setting belt speed.

Metal band saws often feature a feed speed control that determines how long it takes for the band saw to cut through the material. Feed rate is measured in mm/minute. The optimal feed rate setting is determined by tooth pitch, belt speed and chip load (the average amount of material removed per tooth). Higher feed rates increase productivity but often shorten metal band saw life. Finding the lowest cost per cut is often a compromise between productivity and band saw life.

Watch the chips

Observing the chips is a good way to determine whether the belt speed and feed rate of your metal band saw are set correctly. Observe the shape and color of these chips. Normal chips are slightly curled and feel warm to the touch but not hot. The ideal shape resembles a “6” or “9”. If the color of the chips changes from silver to brown, too much heat is generated during cutting, and the linear speed or feed speed or both should be appropriately reduced or the cooling effect should be improved. Blue chips indicate excessive temperatures, a condition that can cause the band saw to fail prematurely. If the correct combination of belt speed and feed speed is selected, the color of the chips will be very similar to the color of the material being cut.

The chip holding capacity of the tooth grooves is another factor that affects sawing efficiency. A metal band saw blade with proper chip holding capacity allows chips to curl evenly and fall out of the tooth grooves. If there are too many chips, they will clog into the groove area, causing greater sawing resistance and generating more heat. This is why deep groove tooth profiles can improve cutting efficiency in medium and low carbon steel materials. But when chip holding capacity is not an issue (such as harder mold steel), this factor does not need to be included in the selection conditions of metal band saw blades. This is also the main reason why the high and low tooth grooves used for cutting stainless steel are designed to be shallower than the tooth grooves of conventional metal band saw blades.

Properly opening metal band saw blades

Before installing a metal band saw blade, the band saw blade must be properly removed from the packaging. Band saw blades are usually folded into several turns or tied into bows, nine-figure knots, etc. for transportation. For optimal metal band saw performance, unfold the metal band saw blade slowly and with hand control. Do not drop it on the floor and allow it to automatically unfold, as this can cause significant damage to the tooth tips. Before using a metal band saw, the tooth tip hitting a hard surface will cause the tooth tip to chip slightly, causing the metal band saw blade to lose part of its cutting performance before use.

Proper Break-in of Metal Bandsaw Blades

After the metal band saw blade is installed, it must be broken in correctly before cutting with normal parameters. Going full speed on the first cut will quickly lead to premature tooth tip chipping. A new metal band saw blade has very sharp tooth tips and is more susceptible to microscopic damage if not properly broken in. Break-in allows the band saw blade to better withstand the strains of cutting.

Bimetallic band saw blades are recommended to be run at half the normal feed rate during the break-in period while maintaining normal band saw speed. Then gradually increase the feed speed and downforce several times until normal cutting speed is reached. It is recommended that the carbide band saw blade be run at about 1/4 of the normal feed rate during the running-in period, and the linear speed of the band saw blade be set to about 50% of the normal speed, and then gradually increase the feed speed and several times of downward force and linear speed. Until the normal parameters are reached, pay attention to the changes in vibration when adjusting the parameters. When the vibration becomes larger, do not rush to increase the feed speed and linear speed. Saw blade break-in can slightly dull the sharp tooth tips, thereby reducing the chance of chipping. Proper break-in of a new band saw blade can significantly extend the life of the band saw. From experience, some running-in is better than no running-in. The tooth tips of coated band saw blades are pre-broken in before leaving the factory and do not need to be broken in on site, so coated band saw blades are an exception.

Basic maintenance checklist for metal band saws

Regular maintenance on a metal band saw is always necessary for correct and efficient sawing, but when it comes to cutting difficult-to-cut materials like high-temperature alloys, it’s more important than ever. In addition to band saw maintenance instructions, refer to the following checklist to help ensure long blade life and efficient operation.

- Pulley – clean up any chips promptly and make sure the pulley rotates freely. Shake the pulley to check if the bearing clearance is too large.

- Bandsaw Tension – Use a tension gauge to make sure the tension is set to normal.

- Bandsaw running trajectory – ensure that the band saw’s trajectory on the saw wheel is appropriate and consistent

- Brush – Install it correctly so that it can properly perform its chip removal function, especially when using carbide band saw blades. This is especially important.

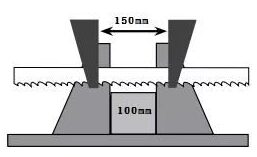

- Guide blocks – Make sure the guide blocks are in good condition. They must hold the band saw blade with the correct pressure and as close as possible to the workpiece being cut.

- Guide Arm – For maximum support of the band saw blade while cutting, place the guide arm as close to the workpiece as possible.

- Cutting Fluid – Make sure to use clean, appropriately concentrated cutting fluid. Use a concentration meter to test and monitor the cutting fluid concentration, and observe its color and foaming with the naked eye. If you need to add new cutting fluid, you must mix it correctly, add water first, and then add the appropriate proportion of lubricant according to the instructions of the cutting fluid.

Many factors can cause early metal band saw blade failure. To maximize the life of your metal band saw, choose the tooth pitch correctly, set the cutting parameters (belt speed and feed speed) correctly, and perform regular maintenance on the band saw itself. Every material has its own unique circumstances, but if you take the time to study all of the factors, you’ll find faster, more cost-effective sawing solutions.