What is the " saw beam strength" of a metal band saw blade?

Whether a metal band saw blade is easy to use depends on its own cutting edge, blade bending and other geometric processing quality and tool material heat treatment quality. The application method on the metal band saw is also very important. The metal band saw blade will be affected by the band saw part. The deformation caused by the force is treated as the deformation and bending ability of the “beam” and solutions are sought. Some material shearing problems can be easily solved.

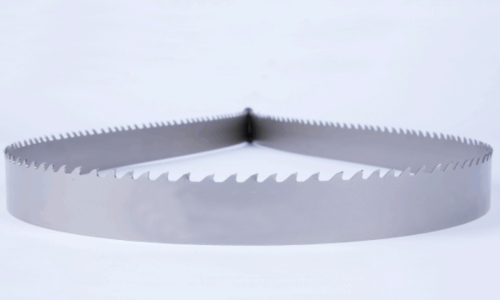

Definition of "saw beam strength" for metal band saw blades

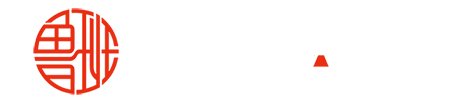

When cutting a workpiece with a metal band saw blade, when the cutting resistance increases due to an increase in feed speed or a change in the cross-section of the material being cut, the tension of the blade on the back side of the band saw blade increases, while the tension on the tooth side decreases, resulting in The material on the back of the tooth edge is compressed, thus making the saw blade arc-shaped, which will tend to cut the workpiece at an angle during sawing. We call this band saw blade resistant to deformation (anti-bending) when it resists sawing resistance during the sawing process. The ability is called the saw beam strength (the same concept as the bending resistance of the beam).

Metal band saw blades with greater “saw beam strength” can withstand higher feed rates and cutting efficiency, resulting in smoother, more precise cuts.

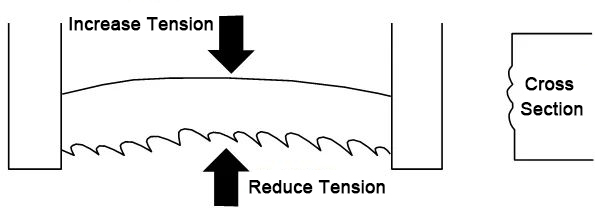

“Saw beam strength” depends on the width and gauge of the metal band saw blade and the distance between the guide arms, the type of band saw machine, the band saw blade tension and the width of the material being cut. Generally, no more than 1/2 of the maximum width specified by the band saw is used. For harder materials, it is safer and more effective to work close to 1/3 of the maximum width, and it is less likely to cause bevel cutting failures.

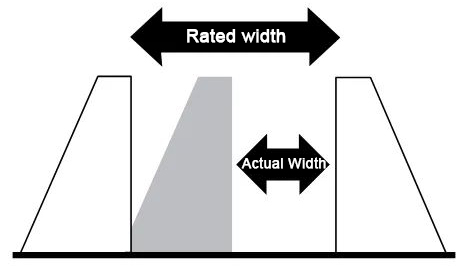

Of course, the “saw beam strength” can also be improved by adjusting the cutting method. For example: a customer needs to cut 80mm square solid bearing steel on a GB4235 (350mm) metal band sawing machine, and the maximum cutting width of the sawing machine is 350mm. The operator In order to cut efficiently, three pieces of material are sawed side by side. Although the width of 240mm is also within the sawing range, in fact, due to the large cutting force per unit length of the bearing steel, when matched in this way, bevel cutting failure is prone to occur and the life of the saw blade is shortened. Therefore, when a single piece of material is sawed, due to the higher “saw beam strength”, the life of the band saw blade is also longer, and the later efficiency will be higher than that of three pieces of side-by-side sawing. Of course, you can also switch the three side-by-side cutting mode to the single cutting mode in the middle and later stages of the use of the metal band saw blade before cutting bevel, because the more the tooth tips of the band saw blade are worn, the higher the “saw beam strength” required. , when a new saw blade is first used, the tooth tips are sharp, the cutting resistance is small, and the “saw beam strength” requirements are relatively lower.

The “saw beam strength” increases as the specifications of the metal band saw blade increase. According to the strength limits per unit length of metal band saw blades of different specifications, the maximum reasonable sawing width of metal band saw blades of various specifications is as follows:

6 ways to ensure the "saw beam strength" of metal band saw blades

1. Calculate the actual maximum cutting width

The actual width of cutting materials is limited to 1/2 of the cutting width of the band saw, and harder materials (above 30HRC) and difficult-to-cut stainless steel, titanium alloy materials, etc. are limited to 1/3.

2. Use a wider metal band saw blade

Wider metal band saw blades and thicker specifications have a greater ability to withstand bending, allowing greater down force and higher feed rates. From a mechanical (moment of inertia) analysis, the bending resistance of metal band saw blades is the same as that of band saw blades. The thickness and width of the saw blade are both positively correlated. The bending resistance (downward) of the 34mm*1.1mm specification with the same 3/4tpi tooth profile is about 2.4 times that of the 27mm*0.9mm bending resistance (excluding the tooth groove depth).

3. Reasonably adjust the position of the guide arm

The “saw beam strength” of a metal band saw blade is inversely proportional to the distance of the guide arm. Place the guide arms as close to the material being processed as possible. The farther away they are, the weaker the support they provide for the metal band saw blade, the worse the bending resistance, the lower the “saw beam strength”, and the easier it is for the saw blade to bend and deform in the plane.

4.Reduce the amount of workpieces placed side by side

After the number of workpieces is reduced, the linear speed and feed speed of the metal band saw can be increased, thereby improving the overall sawing efficiency (the same reason as the third one, the strength of the saw beam is improved).

5. Scientifically place special-shaped materials

Changing the placement of profiled materials in the jaws can reduce cutting resistance and improve cutting efficiency. The principle of adjustment is to ensure the same cutting width as possible throughout the entire cutting stroke. For example, the cutting thickness in the first two pictures below is more reasonable than the placement in the third picture. The cutting resistance encountered in the first two pictures is very uniform throughout the entire stroke, while in the third picture it reaches the bottom. When encountering greater cutting resistance, the required beam strength is higher. Although the bending resistance of the saw blade has not changed, the resistance has changed significantly, causing the saw blade to bend more at the bottom, which may cause the workpiece to cut. incline:

6.Check the tooth tip wear of the metal band saw blade

The gradual wear and tear of the tooth tip of the metal band saw blade makes the saw blade blunt. The blunter the tooth tip is, the metal band saw will cut slower, consume more energy, and the cutting accuracy will gradually become worse when the feed force remains unchanged. When the accuracy of the tooth tip is no longer suitable for cutting wider materials after wear, the number of materials can be reduced and the material can be processed with narrower materials. The blunter the tooth tip, the greater the “saw beam strength” requirement.

In short, when making cutting plans and parameter selections for metal band saws, try to control the amount of in-plane elastic bending deformation of the metal band saw blade during sawing, which can extend the use time of the metal band saw blade.